In the wave of industrial digital transformation, various advanced equipments are constantly emerging, and industrial control all-in-one machines are one of the most popular ones. For many people who are new to the field of industrial automation, they may not know much about the specific uses of industrial control all-in-one machines. Let me analyze it in detail for you.

1. Definition of industrial control all-in-one machine

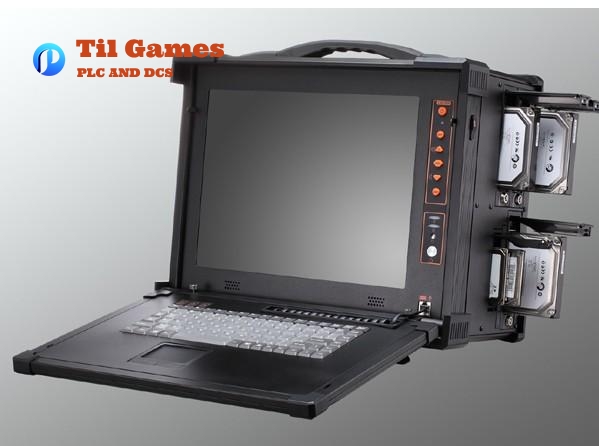

Industrial control all-in-one machine, that is, industrial control all-in-one machine, is a special computer device that highly integrates the host, display, touch screen and other components of industrial computers. It combines the stable and reliable performance of industrial computers with the convenience of integrated design. It does not need to connect multiple independent devices like traditional industrial control systems. It provides a one-stop solution for industrial control and can directly realize data collection, processing, storage and human-computer interaction functions on the industrial site.

2. Characteristics of industrial control all-in-one machine

Highly integrated: integrating the host, display, touch screen, etc. into one, reducing the connection cables between devices, reducing the failure points, and saving installation space. In the industrial control cabinet with limited space, the industrial control all-in-one machine can be easily installed without complex wiring, which greatly improves the simplicity and reliability of the system.

Strong stability: It uses industrial-grade hardware components, such as industrial motherboards, high-quality power supplies, etc., and has excellent anti-interference ability and heat dissipation performance. Whether facing strong electromagnetic interference in factory workshops or harsh environments such as high temperature and high humidity, it can operate stably to ensure accurate data processing and normal control of equipment during industrial production.

Rich interface configuration: It is equipped with various types of interfaces, such as RS232, RS485, Ethernet interface, USB interface, etc., which are convenient for connecting with various industrial sensors, actuators, printers and other equipment to achieve fast data transmission and collaborative work between devices.

3. Classification of industrial control all-in-one computers

Classification by screen size: There are small industrial control all-in-one computers, with a screen size of generally about 7-10 inches, small size, easy to carry and install in small equipment or places with limited space, and are often used for smart home control, small automation equipment, etc.; medium-sized industrial control all-in-one computers have a screen size of 15-21 inches, which is suitable for monitoring and operation of most industrial automation production lines; large industrial control all-in-one computers have a screen size greater than 21 inches, which are usually used in scenes with high requirements for display content and require multiple people to view at the same time, such as large monitoring centers.

Classification by touch screen type: resistive touch screen industrial control integrated machine, which works on the principle of pressure sensing, has high touch accuracy and is suitable for operation with gloves in industrial environments; capacitive touch screen industrial control integrated machine, which uses human electric field sensing technology, has fast response speed and smooth operation, and is often used in scenarios with high requirements for touch experience.

4. Application scenarios of industrial control integrated machine

Industrial automation production line: In automated production lines such as automobile manufacturing and electronic equipment production, industrial control integrated machine is used as a human-machine interaction interface. Operators can use it to monitor various parameters in the production process in real time, such as equipment operation status, product quality data, etc., and can directly issue operation instructions on the screen to achieve precise control of the production process.

Intelligent warehousing and logistics: In intelligent warehousing systems, industrial control integrated machines are used for goods in and out of warehouse management, inventory counting, and control of automated handling equipment. Forklift drivers can receive cargo handling tasks and view cargo storage locations through the industrial control integrated machine installed on the vehicle, thereby improving the efficiency and accuracy of warehousing and logistics.

Energy monitoring and management: In energy industries such as electricity, oil, and natural gas, industrial control integrated machines are used for monitoring and scheduling of energy production processes. Real-time display of operating parameters and energy consumption data of energy production equipment helps managers to promptly discover equipment failures and energy waste problems, and achieve efficient use and optimized management of energy.

Medical equipment and health management: In the medical field, industrial control all-in-one computers are used for the control and data management of medical equipment, such as the operating interface of medical imaging equipment and the patient monitoring system in hospital wards. Medical staff can view the patient’s vital signs data in real time through the industrial control all-in-one computer, and conduct remote diagnosis and treatment plan formulation.

5. Advantages of industrial control all-in-one computers

Compared with traditional industrial control systems, industrial control all-in-one computers have obvious advantages. Its integrated design greatly shortens the system construction time, reduces installation costs and maintenance difficulties. At the same time, due to the high degree of equipment integration, compatibility issues between devices are reduced, and the overall stability of the system is improved. In terms of human-computer interaction, the application of touch screens makes the operation more convenient and intuitive, without the need for professional computer operation skills, reducing the learning cost of operators and improving work efficiency.

In summary, industrial control all-in-one computers have become indispensable equipment in the industrial field with their unique advantages and wide application scenarios. With the continuous development of industrial technology, the performance and functions of industrial integrated computers will continue to improve, injecting strong impetus into the development of industrial automation and intelligence. Whether it is the automated production line of a large enterprise or the intelligent transformation of a small factory, industrial integrated computers can play an important role and help the industrial field move to a higher stage of development.