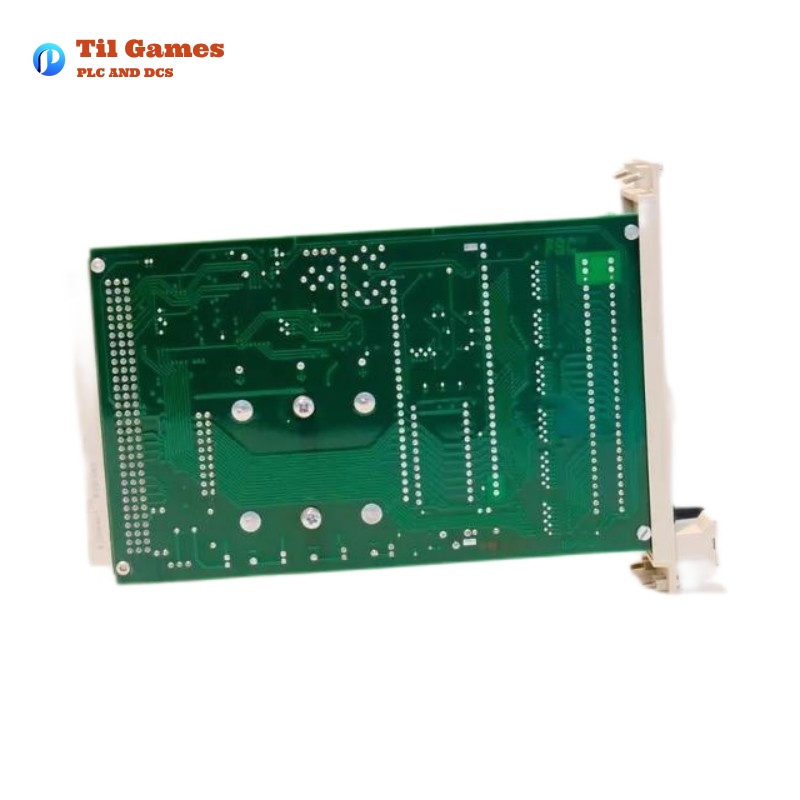

Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Specifications

The following table provides the detailed technical specifications of the Honeywell 10006/2/1 module:

| Attribute | Specification |

|---|---|

| Manufacturer | Honeywell |

| Product Number | 10006/2/1 |

| Product Type | 3400310 Diagnostic and Battery Module (DBM) |

| Type Number | 10006/2/1 08801* |

| Approvals | CE, TÜV, UL |

| Software Versions | = 2.90 |

| Space Requirements | 8 TE, 3 HE (= 8 HP, 3U) |

| Time Drift | < 1 sec/day |

| Power Requirements | 5 Vdc 300 mA |

| Ripple Content | < 50 mV p-p |

| Back-up Capacity | 0.5 Ah |

| Noise Immunity | Improved for modules with suffix 08801 |

| Weight | 0.24 Kg |

| Dimensions | Height: 130mm, Width: 40.3mm |

Product Introduction

The Honeywell 10006/2/1 Diagnostic and Battery Module (DBM) is a crucial component of the Fail-Safe Controller (FSC) system, providing a reliable and cost-effective interface for diagnostic monitoring and backup power management. The module ensures that the system operates efficiently by reducing time drift and offering a robust backup capacity.

The 10006/2/1 DBM is designed to enhance the stability of FSC systems by ensuring minimal time drift (<1 sec/day) and delivering high noise immunity, especially in models with suffix code 08801. With CE, TÜV, and UL certifications, the module meets international safety and quality standards.

This module is widely used in industries requiring high reliability, such as oil and gas, petrochemical, and power generation.

Applications

The 10006/2/1 DBM is ideal for various industrial applications, including:

- Process Automation – Ensures the integrity of safety systems by maintaining accurate diagnostic information.

- Oil and Gas – Provides essential monitoring and backup for critical control systems.

- Petrochemical Industry – Supports safety instrumented systems (SIS) in hazardous environments.

- Power Generation – Maintains stable performance in control and monitoring systems.

- Manufacturing Plants – Enhances reliability in automated safety processes.

- Refineries – Ensures secure and stable operation of monitoring systems.

- Pharmaceuticals – Supports precision diagnostics in controlled environments.

- Water Treatment Plants – Ensures uninterrupted data recording and diagnostics.

- Aerospace and Defense – Provides critical diagnostic functions in mission-critical systems.

- General Industrial Control – Supports a broad range of automation and monitoring applications.

Product Advantages

The Honeywell 10006/2/1 DBM offers several advantages, making it a preferred choice for industrial applications:

- High Reliability – Designed for mission-critical environments with improved noise immunity.

- Low Power Consumption – Operates efficiently at 5V DC, 300 mA.

- Minimal Time Drift – Ensures accurate system performance with a <1 sec/day time drift.

- Backup Power Support – Equipped with 0.5 Ah backup capacity to maintain system stability.

- Compact Size – Fits standard 3U rack configurations, saving space in control cabinets.

- International Certifications – Approved by CE, TÜV, and UL, ensuring compliance with global standards.

- Enhanced Diagnostic Capabilities – Provides comprehensive system health monitoring.

- Robust Design – Engineered for use in harsh industrial environments.

- Easy Integration – Seamlessly integrates into existing Honeywell FSC systems.

- Long-Term Cost Savings – Reduces maintenance costs by offering a low-cost diagnostic interface.

Latest News on the Product

- “Honeywell Enhances FSC System Stability with New 10006/2/1 Diagnostic and Battery Module”

- “Improved Noise Immunity in Honeywell 10006/2/1 DBM Boosts Reliability in Industrial Automation”

- “Safety System Diagnostics: Honeywell 10006/2/1 Module Plays a Key Role in Process Control”

- “Oil and Gas Operators Choose Honeywell 10006/2/1 DBM for High-Performance Safety Applications”

- “New Advancements in FSC Technology: Honeywell 10006/2/1 Delivers Improved Monitoring Capabilities”

Related Models in the Same Series

| Model | Description |

|---|---|

| 10006/2/1 | Diagnostic and Battery Module (DBM) |

| 10024/I/F | Input/Output Module for FSC |

| 10018/E/1 | FSC Power Supply Module |

| 10005/1/1 | Watchdog Module |

| 10101/2/1 | Safety Communication Module |

| 10201/2/1 | Advanced Diagnostic Module |

| 10302/3/1 | Redundant Safety Processor |

| 10025/1/1 | FSC Interface Module |

| 10012/1/2 | High-Speed Communication Module |

| 10105/2/1 | Digital Output Module |

Popular Honeywell Industrial Control Models

| Model | Description |

|---|---|

| C300 | Process Control CPU |

| C200E | Enhanced Process Controller |

| FC-SDIL-1608 | Digital Input Module |

| FC-TSDO-0824 | Digital Output Module |

| 900RSM-0200 | Redundant Switch Module |

| FC-PSU-UNI2450U | Power Supply Module |

| 900P01-0301 | Industrial Power Supply |

| 10005/1/1 | Watchdog Module |

| FC-SAI-1620M | Analog Input Module |

| SPS5710 | Industrial Power Supply |

FAQ

FAQs (Frequently Asked Questions)

Q1: What is the primary function of the Honeywell 10006/2/1 DBM?

A: It provides a low-cost interface for diagnosing FSC system performance and includes backup power management.

Q2: What certifications does the 10006/2/1 DBM have?

A: It is CE, TÜV, and UL certified, ensuring compliance with international safety and quality standards.

Q3: How does the improved noise immunity benefit the system?

A: The suffix code 08801 version of the module reduces signal interference, enhancing system stability.

Q4: What is the backup capacity of the module?

A: The 0.5 Ah backup capacity ensures short-term power support during fluctuations.

Q5: What are the power requirements for this module?

A: It operates at 5V DC, 300 mA.

Q6: Can this module be used in non-Honeywell systems?

A: While designed for Honeywell FSC systems, integration with other systems depends on compatibility.

Q7: What are the space requirements for installation?

A: It requires 8 TE, 3 HE (8 HP, 3U) of rack space.

Q8: How often does the module need maintenance?

A: It requires minimal maintenance, but periodic checks are recommended for optimal performance.

Q9: What industries commonly use this module?

A: It is widely used in oil and gas, power generation, petrochemical, and manufacturing industries.

Q10: How does this module ensure accuracy?

A: It has a time drift of <1 sec/day, ensuring precise diagnostic reporting.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.