Products Description

| Company Information | |||

| sales@xmjzjsgs.com | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Specifications

| Parameter | Description |

|---|---|

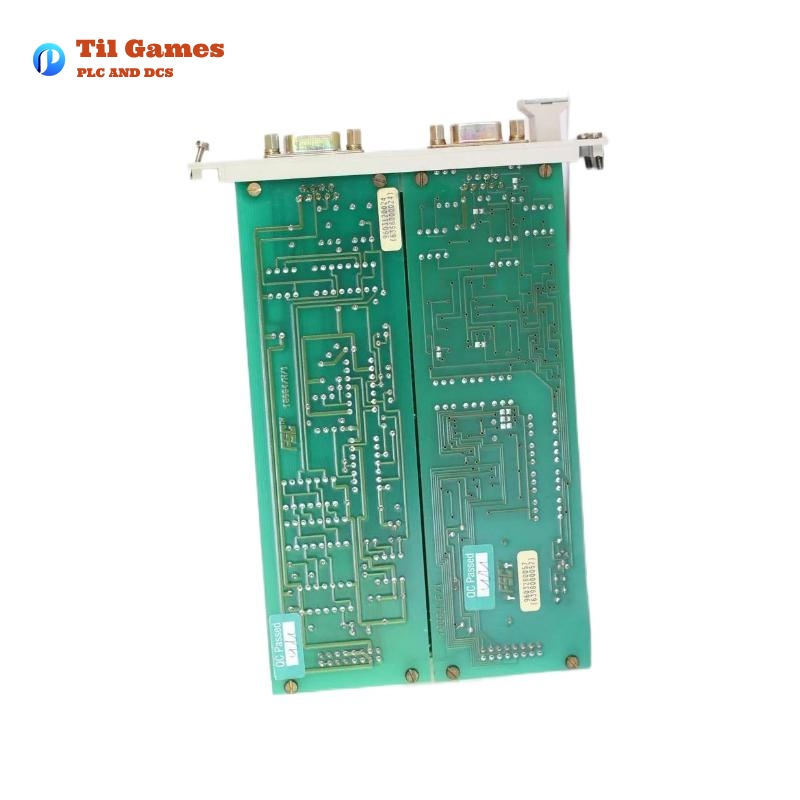

| Model | 10004/H/F |

| Manufacturer | Honeywell |

| Product Type | Communication Module |

| Dimensions | 20.32 × 33.34 × 160 mm |

| Weight | 0.5 kg |

| Power Supply | 24V DC |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 5% to 95% (non-condensing) |

| Communication Protocol | Proprietary Honeywell Protocol |

| Interface Type | Serial, Ethernet (if applicable) |

| Baud Rate | Up to 115.2 kbps (if serial) |

| Mounting Type | DIN Rail or Rack Mount |

| Enclosure Rating | IP20 or higher (dependent on configuration) |

| Compliance Standards | CE, FCC, RoHS, UL |

Product Introduction

The Honeywell 10004/H/F Communication Module is a highly reliable and efficient communication interface designed for industrial automation and control systems. This module enables seamless data exchange between controllers, field devices, and central monitoring systems, ensuring real-time operational visibility and enhanced process control.

With advanced communication capabilities, the module supports various industrial communication protocols, ensuring compatibility with a wide range of Honeywell control systems. Its compact design and robust construction make it suitable for use in demanding industrial environments, offering both performance and longevity.

Product Applications

The Honeywell 10004/H/F Communication Module is widely used in industries requiring high-performance automation and communication solutions. Some key application areas include:

- Oil and Gas: Used in SCADA systems for real-time data acquisition and process control.

- Power Plants: Facilitates communication between distributed control systems (DCS) and field instruments.

- Chemical and Petrochemical: Ensures safe and reliable data transfer for process monitoring and control.

- Manufacturing Automation: Integrates PLCs, sensors, and actuators to streamline production processes.

- Water and Wastewater Treatment: Enables remote monitoring and control of water treatment facilities.

- Pharmaceuticals: Supports precise data communication in automated production lines.

- Mining and Metals: Ensures robust communication in harsh industrial environments.

Product Advantages

- Reliable and Stable Performance: Designed for continuous operation in mission-critical industrial environments.

- Flexible Communication: Supports multiple industrial communication protocols for seamless integration.

- Compact and Durable Design: Small form factor with industrial-grade build quality ensures durability.

- Easy Installation and Maintenance: Simple mounting options and user-friendly configuration.

- High-Speed Data Transfer: Optimized for real-time communication and low-latency data exchange.

- Wide Operating Temperature Range: Functions effectively in extreme environmental conditions.

- Industry Compliance: Meets stringent safety and reliability standards such as CE, FCC, RoHS, and UL.

- Scalability: Can be easily integrated into existing Honeywell control systems for future expansion.

- Energy-Efficient: Consumes low power while maintaining optimal performance.

- Enhanced Security: Built-in security features prevent unauthorized access to the control system.

Latest News and Updates

Here are some recent updates related to Honeywell industrial automation and communication technologies:

- “Honeywell Introduces Next-Generation Industrial Communication Modules for Enhanced Connectivity”

- “Innovations in Industrial Communication: How Honeywell is Shaping the Future of Automation”

- “Honeywell Expands Its Industrial Automation Portfolio with New Communication Solutions”

- “Cybersecurity in Industrial Communication: Honeywell’s Approach to Secure Data Transfer”

- “Case Study: How Honeywell Communication Modules Improve Operational Efficiency in Power Plants”

- “The Future of Industrial Connectivity: Honeywell’s Role in Industry 4.0”

- “Honeywell Enhances DCS Communication Capabilities with Advanced Network Modules”

- “Reducing Downtime: The Impact of Honeywell Communication Modules in Manufacturing”

- “Smart Factories and Honeywell: A Look into Advanced Automation Solutions”

- “Honeywell’s Latest Developments in Secure and Reliable Industrial Communication”

Recommended Related Models

Here are 10 models from the same series or related Honeywell communication modules:

| Model | Description |

|---|---|

| 10005/1/1 | Watchdog Module for industrial systems |

| 10101/2/1 | Communication Processor Module |

| 10310/1/1 | Network Interface Module |

| 10402/1/1 | High-Speed Data Transfer Module |

| 10503/H/F | Serial Communication Module |

| 10600/2/1 | Multi-Protocol Gateway Module |

| 10701/H/F | Fiber Optic Communication Module |

| 10802/1/1 | Redundant Network Interface Module |

| 10900/H/F | Industrial Ethernet Communication Module |

| 11004/H/F | Advanced Fieldbus Communication Module |

Popular Honeywell Models

Here are 10 popular Honeywell automation and control models:

| Model | Description |

|---|---|

| C300 Controller | High-performance process control unit |

| Safety Manager | Integrated safety system for critical applications |

| 900RSM-0200 | Redundant Switch Module for secure networking |

| FC-SAI-1620M | Analog Input Module for precise signal acquisition |

| FC-TSRO-0824 | Digital Output Module for industrial applications |

| 51199929-100 | SPS5710 Power Supply Module |

| 10005/1/1 | Watchdog Module for Honeywell control systems |

| UCN Bridge Module | Communication interface for Universal Control Network |

| Experion PKS | Advanced process knowledge system |

| HC900 Controller | Hybrid control system for complex industrial processes |

FAQ

Frequently Asked Questions (FAQ)

Q1: What is the function of the Honeywell 10004/H/F Communication Module?

A1: It enables seamless communication between industrial control systems and field devices.

Q2: What are the dimensions and weight of the module?

A2: The dimensions are 20.32 × 33.34 × 160 mm, and the weight is 0.5 kg.

Q3: Which communication protocols does this module support?

A3: It supports proprietary Honeywell communication protocols, with possible Ethernet or serial options.

Q4: What is the operating temperature range?

A4: It operates between -25°C to +70°C.

Q5: Is this module compatible with Honeywell DCS systems?

A5: Yes, it is designed for integration with Honeywell Distributed Control Systems (DCS).

Q6: What industries commonly use this module?

A6: It is widely used in oil & gas, power plants, manufacturing, water treatment, and more.

Q7: How is the module mounted?

A7: It can be mounted using DIN rail or rack mounting options.

Q8: Does this module require any specific software for configuration?

A8: Yes, it typically requires Honeywell’s configuration software or engineering tools.

Q9: What is the power supply requirement?

A9: It operates on 24V DC power supply.

Q10: Where can I purchase this module?

A10: Contact us.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.