Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Description

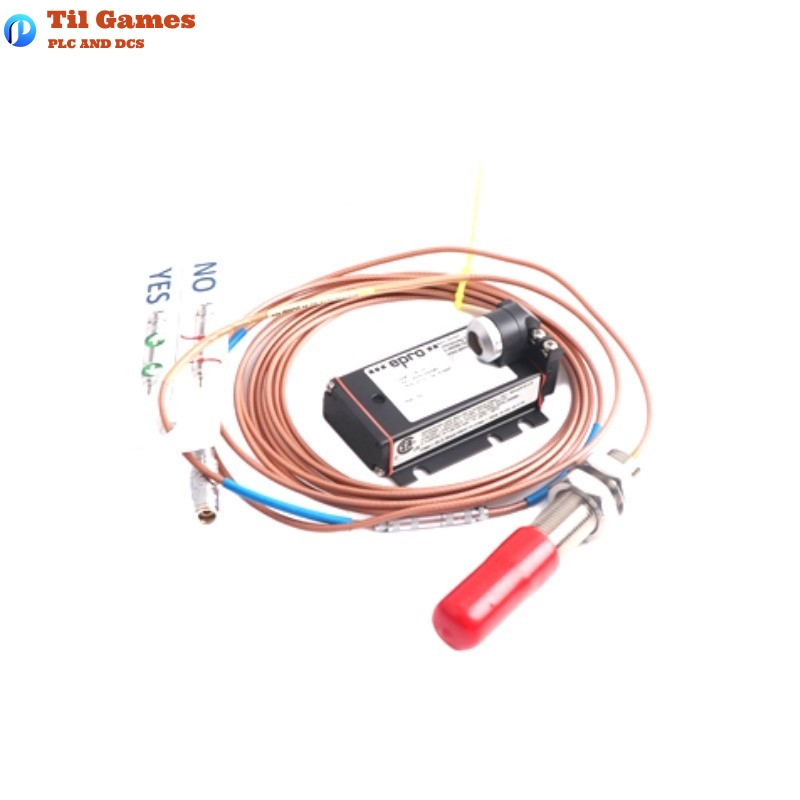

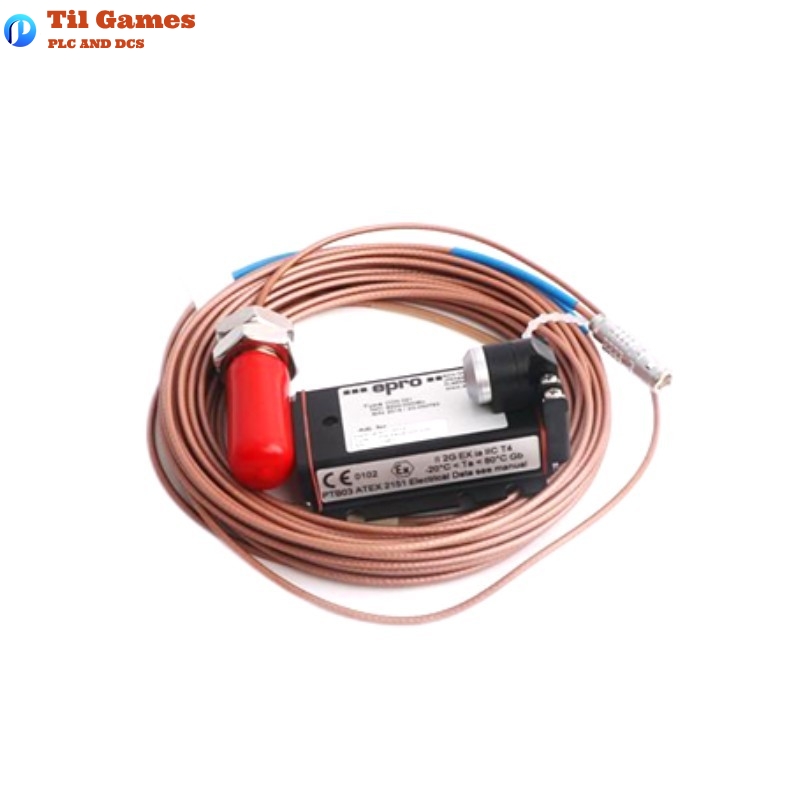

The Epro PR6424/003-030 is a 16mm eddy current sensor engineered for non-contact vibration, displacement, and position monitoring of rotating machinery. Developed by Epro, now under Emerson’s AMS product line, this sensor is widely deployed in industrial environments where high accuracy and robustness are crucial — including turbines, compressors, pumps, and large fans.

The PR6424 series sensors interface with CON and CON041 signal converters, allowing precise measurements of shaft dynamic displacement, position, eccentricity, and rotational speed. The model PR6424/003-030 features a rugged stainless-steel construction, high-pressure resistance, and wide temperature operating ranges, making it suitable for hazardous and demanding applications.

Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | PR6424/003-030 |

| Sensor Type | Eddy Current Displacement Sensor |

| Sensing Principle | Non-contact electromagnetic induction |

| Sensitivity / Linearity | 4 V/mm (101.6 mV/mil), ≤ ±1.5% |

| Static Measurement Range | ±2.0 mm (0.079”) |

| Dynamic Measurement Range | 0 to 1,000 µm (0 to 0.039”) |

| Target Material | Ferromagnetic steel (e.g., 42CrMo4) |

| Shaft Diameter | ≥ 80 mm |

| Center Air Gap | ~2.7 mm (0.11”) nominal |

| Long-Term Drift | < 0.3% |

| Max Surface Speed | 2,500 m/s (98,425 ips) |

| Operating Temperature Range | -35°C to +150°C (-31°F to +302°F) |

| Temperature Drift | < 4% per 100K (API 670 compliant) |

| Pressure Resistance | Up to 10,000 hPa (145 psi) |

| Vibration Resistance | 5g @ 60 Hz @ 25°C |

| Material | Sleeve: Stainless Steel; Cable: PTFE |

| Compliance Certifications | CE, ATEX, IEC-Ex, CSA, UL |

| Hazardous Area Ratings | T3/T4/T6 depending on temperature and converter used |

| Weight (Sensor + 1m Cable, no armor) | ~0.2 kg (200 grams) |

| Sensor Head Diameter | 16 mm |

| Thread Type | M18x1.5 |

Product Features

-

Non-contact eddy current technology for high precision.

-

Compact and robust 16 mm diameter stainless steel housing.

-

Pressure and temperature resistant for harsh conditions.

-

High linearity and minimal drift for reliable long-term performance.

-

Interchangeable with Epro CON/CON041 signal converters.

-

Conforms with major global certifications and safety standards.

-

Suited for both static and dynamic measurement environments.

Product Advantages

-

Durability: Designed for extreme industrial conditions, offering long service life even in high-vibration or high-pressure zones.

-

Precision Monitoring: Exceptional sensitivity and stability enable accurate condition-based maintenance.

-

Global Compliance: Certified for ATEX, IEC-Ex, CSA, and CE, facilitating safe deployment across industries.

-

Modular Design: Compatible with a variety of converter options and cable configurations to suit diverse applications.

-

Compact Footprint: The 16 mm sensing head allows for integration into space-constrained machinery setups.

-

Wide Temperature Range: Operates in extreme environments from -35°C to +150°C.

Typical Applications

-

Steam Turbines

-

Gas Turbines

-

Hydraulic Turbines

-

Centrifugal Compressors

-

Industrial Fans

-

High-speed Pumps

-

Motor and Gearbox Monitoring

-

Rotating Equipment in Oil & Gas, Power Generation, Petrochemical Plants

Latest Industry Report Title Featuring This Product

“Enhanced Reliability Monitoring in High-Speed Rotating Equipment Using Epro PR6424 Series Sensors – Emerson AMS Innovations for 2024”

Recommended Related Models from the Same Series

| Model | Description | Sensor Diameter | Measurement Range | Weight |

|---|---|---|---|---|

| PR6424/002-030 | Eddy current sensor, 16mm, static & dynamic range | 16 mm | ±2 mm static, 0–1000 μm | 0.2 kg |

| PR6424/004-030 | Extended range variant, hazardous area compatible | 16 mm | ±2.5 mm | 0.2 kg |

| PR6424/006-030 | Armored cable version for high vibration zones | 16 mm | ±2.0 mm | 0.2 kg |

| PR6424/005-030 | High temp tolerance variant with armored sheath | 16 mm | ±2.0 mm | 0.2 kg |

| PR6424/007-030 | Long cable model for extended mounting distance | 16 mm | ±2.0 mm | 0.2 kg |

| PR6424/008-030 | Enhanced drift control version | 16 mm | ±1.8 mm | 0.2 kg |

Popular Epro Models Recommended

| Model | Function | Application | Sensor Diameter | Weight |

|---|---|---|---|---|

| PR6423/000-030 | 8 mm Eddy Current Sensor | Limited space turbomachinery | 8 mm | 0.1 kg |

| PR6425/000-030 | 25 mm Eddy Current Sensor | Heavy-duty shaft vibration monitoring | 25 mm | 0.35 kg |

| CON021 | Signal Converter for PR6422/23/24 Series | Converts sensor output to processable signal | – | 0.4 kg |

| CON041 | High-performance Converter | Advanced monitoring setups | – | 0.4 kg |

| MMS6110 | Rack-based Monitoring System | Turbomachinery protection & diagnostics | – | 2.5 kg |

| PR6420/000-030 | Proximity Probe | For non-critical or OEM applications | 10 mm | 0.15 kg |

FAQ

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the PR6424/003-030 sensor?

A1: It is designed for non-contact measurement of shaft displacement, position, and vibration in rotating machinery such as turbines and compressors.

Q2: What material should the shaft be for accurate measurement?

A2: The sensor is optimized for ferromagnetic steel targets, particularly 42CrMo4 standard steel.

Q3: What is the operating temperature range of this sensor?

A3: It operates between -35°C and +150°C, making it suitable for harsh environments.

Q4: Can this sensor be used in hazardous zones?

A4: Yes, the sensor is certified under ATEX, IEC-Ex, and CSA standards for hazardous area usage.

Q5: What is the default thread type of the sensor?

A5: The default mechanical thread for mounting is M18x1.5.

Q6: Is the cable armored by default?

A6: No, the PR6424/003-030 comes with a non-armored cable by default. Armored versions are available upon request.

Q7: What converters are compatible with this sensor?

A7: It is compatible with Epro/Emerson CON041 and CON021 signal converters.

Q8: What is the recommended minimum shaft diameter for accurate measurement?

A8: The shaft should be at least 80 mm in diameter for optimal accuracy.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.