Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Description

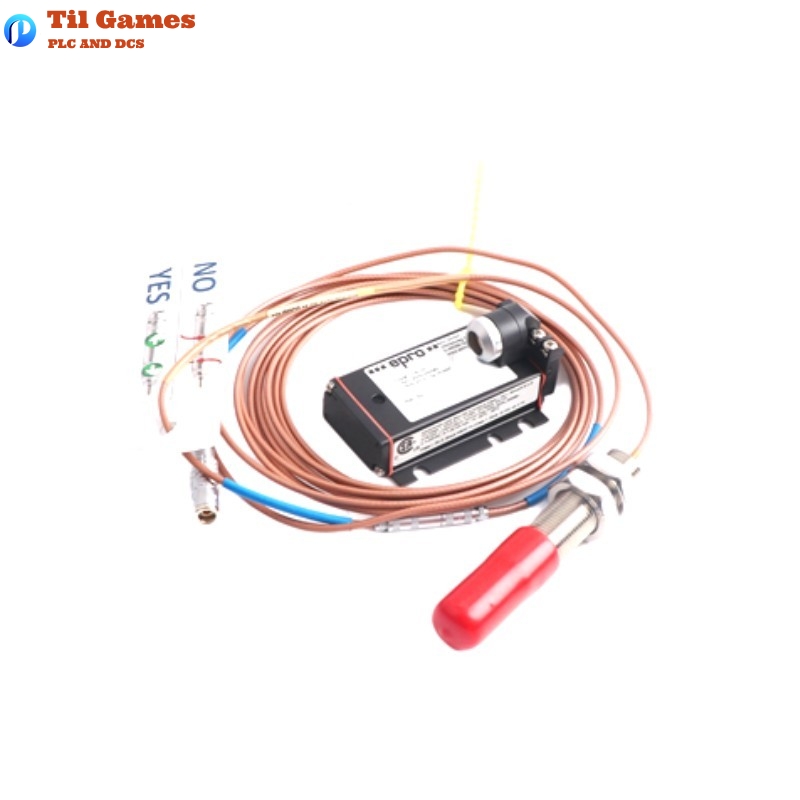

The Epro PR6424/000-010 is a precision-engineered non-contact eddy current sensor designed for use in demanding industrial environments, especially in turbomachinery monitoring. The sensor is ideal for monitoring the radial and axial dynamic displacement, shaft position, eccentricity, and rotational speed in machinery such as steam turbines, gas turbines, hydro turbines, compressors, pumps, and fans. This sensor ensures reliable performance in extreme conditions, helping users comply with international standards like API 670.

The 16mm sensor head provides superior sensitivity and stable long-term performance, backed by rugged materials and wide compatibility with machinery monitoring systems.

Product Specifications

| Parameter | Value |

|---|---|

| Sensor Type | Eddy Current Sensor |

| Model | PR6424/000-010 |

| Sensor Head Diameter | 16 mm |

| Weight | ~0.2 kg (200 g) |

| Sensitivity / Linearity | 4 V/mm (101.6 mV/mil) ≤ ±1.5% |

| Nominal Air Gap (Center) | Approx. 2.7 mm (0.11”) |

| Long-Term Drift | < 0.3% |

| Static Measurement Range | ±2.0 mm (0.079”) |

| Dynamic Measurement Range | 0 to 1,000 μm (0 to 0.039”) |

| Target Material | Ferromagnetic Steel (42CrMo4) |

| Max Surface Speed | 2,500 m/s (98,425 ips) |

| Shaft Diameter | ≥ 80 mm |

| Operating Temperature Range | -35°C to +150°C (-31°F to +302°F) |

| Temperature Error | < 4% / 100K |

| Pressure Resistance | 10,000 hPa (145 psi) |

| Shock/Vibration Resistance | 5g @ 60Hz @ 25°C |

| Material (Sleeve / Cable) | Stainless Steel / PTFE |

| Certifications | CE, ATEX, IECEx, CSA, UL |

| Hazardous Area Approvals | ATEX/IEC-Ex/CSA (T3/T4/T6 ratings) |

| Typical Cable Length Options | 4m, 5m, 8m, 10m |

| Cable End Options | LEMO or Open End |

Product Features

-

Non-contact sensing technology for wear-free operation

-

High linearity and sensitivity (4 V/mm) for accurate vibration and displacement monitoring

-

Robust stainless steel sleeve ensures mechanical durability

-

Wide operational temperature range (-35 to +150°C) suitable for harsh environments

-

Ferromagnetic target material compatibility (42CrMo4)

-

Supports API 670 compliance

-

Multiple hazardous area certifications (ATEX, IECEx, CSA, UL)

-

Customizable lengths and cable configurations

Product Advantages

-

Enables predictive maintenance by detecting early-stage mechanical degradation

-

Supports high-speed rotating equipment with surface speeds up to 2,500 m/s

-

Excellent signal stability and low drift over time

-

Designed for use in mission-critical turbomachinery environments

-

Flexibility in installation with options for thread types, cable lengths, and armor

-

Proven field reliability under high pressure and vibration exposure

-

Compatible with Emerson’s VM600 and MMS series monitoring systems

Typical Applications

-

Steam turbines

-

Gas turbines

-

Hydro turbines

-

Industrial pumps

-

Centrifugal and axial compressors

-

Industrial fans

-

Rotating machinery in petrochemical, power, and process industries

Latest Published News Titles (2024–2025)

-

“Emerson Expands Epro PR6424 Series for High-Speed Turbomachinery Reliability”

-

“PR6424 Sensor Achieves New Standards in Shaft Vibration Monitoring”

-

“Eddy Current Sensors Gain Market Traction in Predictive Maintenance Systems”

-

“Upgraded Certification for Epro PR6424 Enhances Global Usability”

-

“High-Temperature Stability: PR6424 Sets New Benchmark”

Recommended Models from the Same or Related Series

| Model | Description | Sensor Head | Weight | Sensitivity | Application |

|---|---|---|---|---|---|

| PR6424/000-030 | Standard sensor with armored cable | 16 mm | ~0.2 kg | 4 V/mm | Turbines, compressors |

| PR6424/010-010 | High-temp sensor with long probe | 16 mm | ~0.2 kg | 4 V/mm | High-temp rotating machinery |

| PR6423/000-010 | 5 mm eddy current sensor | 5 mm | ~0.15 kg | 7.87 V/mm | Compact installations |

| PR6425/000-010 | 25 mm eddy current sensor | 25 mm | ~0.3 kg | 2 V/mm | Large shafts and wide gap ranges |

| PR6426/000-010 | 10 mm eddy current sensor | 10 mm | ~0.18 kg | 5.7 V/mm | Standard motors, pumps |

| PR6424/000-060 | Long-body sensor with armored cable and LEMO plug | 16 mm | ~0.2 kg | 4 V/mm | Remote mounting in harsh environments |

Popular Epro Models

| Model | Description | Sensor Head | Weight | Sensitivity | Application |

|---|---|---|---|---|---|

| PR6423/000-030 | Compact 5 mm eddy current sensor | 5 mm | ~0.15 kg | 7.87 V/mm | Turbine monitoring |

| PR6424/000-010 | 16 mm eddy current sensor | 16 mm | ~0.2 kg | 4 V/mm | Radial/axial displacement |

| PR6425/000-010 | 25 mm eddy current sensor | 25 mm | ~0.3 kg | 2 V/mm | Large rotating machinery |

| PR6426/000-040 | 10 mm with extended cable support | 10 mm | ~0.18 kg | 5.7 V/mm | General-purpose industrial applications |

| PR6420/000-030 | High-precision temperature sensor | — | — | — | Thermal condition monitoring |

| CON021/PR6423 | Vibration module with sensor integration | — | — | — | Combined displacement & vibration |

FAQ

Frequently Asked Questions (FAQ)

Q1: What is the primary application of the PR6424/000-010 sensor?

A1: It is used to monitor shaft displacement, position, and vibration in high-speed rotating machinery like turbines and compressors.

Q2: What materials are compatible with this sensor?

A2: The sensor is designed for ferromagnetic materials, specifically 42CrMo4 standard steel.

Q3: Can the PR6424 sensor be used in hazardous environments?

A3: Yes, it is certified under ATEX, IECEx, CSA, and UL standards for hazardous area use.

Q4: What are the available options for cable and connectors?

A4: Users can choose from cable lengths (4m, 5m, 8m, 10m), armored or non-armored, and LEMO or open cable ends.

Q5: What temperature conditions can the sensor withstand?

A5: It can operate in environments ranging from -35°C to +150°C.

Q6: What is the expected measurement accuracy?

A6: The sensor provides a sensitivity of 4 V/mm with linearity within ±1.5%.

Q7: What shaft size is required for this sensor?

A7: The minimum recommended shaft diameter is 80 mm.

Q8: Is the sensor suitable for use in compliance with API 670?

A8: Yes, the PR6424 sensor series is fully compliant with API 670 vibration monitoring standards.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.