Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Specifications

The following table provides the detailed technical specifications of the A6500-UM Universal Measurement Card:

| Parameter | Specification |

|---|---|

| Dimensions | 100 mm x 160 mm |

| Weight | 0.2 kg |

| Nominal Voltage | +24 V DC (redundant supply voltage) |

| Voltage Range | +19 V to +32 V DC |

| Overvoltage Protection | Shuts down at >+33 V DC |

| Power Consumption | 6 W |

| Connector Type | 48-pole connector (IEC 60603-2, F 48 M) |

| Measurement Channels | 2 channels |

| Measuring Parameters | Dynamic values, static values, speed |

| Compatible Sensors | Eddy current, electrodynamic, piezoelectric, Hall-effect, VR sensors |

| Alarm Outputs | Digital outputs and Modbus communication |

| Mounting System | A6500-xR System Racks (A6500-SR, A6500-RR, A6500-FR) |

Product Introduction

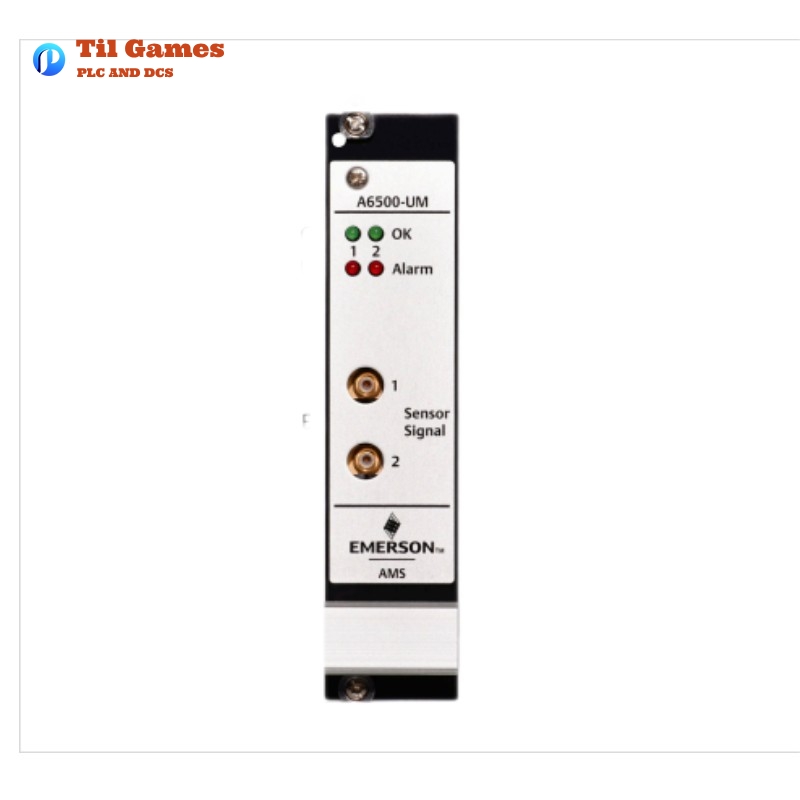

The A6500-UM Universal Measurement Card is an integral part of Emerson’s AMS 6500 ATG system, designed for advanced vibration monitoring and machine protection. The card provides precise measurement of dynamic, static, and speed parameters, enabling efficient condition monitoring of rotating machinery.

It supports multiple sensor types including eddy current, electrodynamic, and piezoelectric sensors for measuring shaft vibrations, bearing conditions, and rotational speed. The card features advanced signal processing with Butterworth filters and supports Modbus and OPC UA communication for integration with broader industrial monitoring systems.

Product Applications

The A6500-UM is designed for a wide range of industrial applications, including:

- Turbomachinery Monitoring: Measures shaft vibrations, bearing conditions, and rotor dynamics.

- Reciprocating Compressors: Tracks rider band wear, rod drop, and cylinder pressure.

- Pumps and Fans: Ensures balanced operation by monitoring housing expansion and shaft eccentricity.

- Generators and Motors: Monitors absolute shaft vibration and relative shaft positioning.

- Valve Position Monitoring: Uses linear displacement transducers for accurate valve positioning.

- Machine Speed and Direction Detection: Provides real-time rotational speed and directional analysis.

Product Advantages

- Versatile Measurement Capabilities: Supports multiple sensor types and configurable channels for diverse monitoring applications.

- High Precision: Advanced Butterworth filters ensure accurate signal processing.

- Easy Integration: Compatible with Modbus and OPC UA communication protocols.

- Reliable Machine Protection: Continuous monitoring of critical machine health parameters.

- Scalable System: Part of the AMS 6500 ATG system, which can be expanded with additional modules.

- Low Maintenance: Designed for long-term operation without the need for regular maintenance.

Latest News Titles on A6500-UM

- Emerson Expands AMS 6500 ATG with Advanced Vibration Monitoring Card

- New Firmware Update Improves Performance of A6500-UM Universal Measurement Card

- Industrial Machinery Protection Enhanced with Emerson’s A6500-UM Card

- Emerson Introduces Real-time OPC UA Data Integration for AMS 6500 ATG

- Predictive Maintenance Gets a Boost with A6500-UM’s Advanced Signal Processing

- Emerson’s A6500-UM Card Now Supports Additional Sensor Types

- Case Study: How A6500-UM Prevented a Critical Failure in a Gas Turbine

- Remote Monitoring Made Easy with A6500-UM’s Ethernet Integration

- Achieving ISO 10816 Compliance with Emerson’s A6500-UM Card

- Top Industry Experts Praise Emerson’s Innovation in Machinery Health Systems

Related Models in the A6500 Series

Here are 10 models in the A6500 series that are related to A6500-UM:

| Model | Function |

|---|---|

| A6500-CC | Communication card for A6500 system |

| A6500-SR | System rack for A6500 modules |

| A6500-RR | Redundant system rack |

| A6500-FR | Field rack for remote installations |

| A6500-LC | Linear displacement transducer converter |

| A6500-ATG | Advanced vibration monitoring system |

| A6500-TMP | Temperature monitoring module |

| A6500-IO | Input/output module for sensor data |

| A6500-PWR | Power supply module for A6500 system |

| A6500-DSP | Digital signal processing unit |

Top 10 Popular Emerson Models

Apart from the A6500 series, here are 10 popular Emerson industrial monitoring devices:

| Model | Description |

|---|---|

| CSI 2140 | Portable vibration analyzer for predictive maintenance |

| AMS 2140 | Machinery health analyzer |

| CSI 9420 | Wireless vibration transmitter |

| AMS Trex | Device communicator for field instruments |

| AMS 6500 ATG | Advanced vibration monitoring system |

| AMS 2600 | Continuous emission monitoring system |

| Ovation 3.7.1 | Distributed control system (DCS) |

| DeltaV PK | Next-gen process automation system |

| Rosemount 3051 | Smart pressure transmitter |

| Micro Motion ELITE | High-precision Coriolis flow meter |

FAQ

Frequently Asked Questions (FAQ)

Q1: What is the A6500-UM Universal Measurement Card used for?

A1: The A6500-UM is used for measuring dynamic, static, and speed parameters in industrial machinery for condition monitoring and predictive maintenance.

Q2: What types of sensors does the A6500-UM support?

A2: It supports eddy current sensors, electrodynamic sensors, piezoelectric sensors, Hall-effect sensors, and VR sensors.

Q3: How is the A6500-UM integrated into an industrial system?

A3: It is installed in A6500-xR System Racks and communicates with AMS Machine Studio via Modbus and OPC UA.

Q4: What industries typically use the A6500-UM?

A4: It is widely used in power plants, oil & gas, manufacturing, and water treatment facilities.

Q5: Can the A6500-UM monitor multiple machines simultaneously?

A5: Yes, multiple A6500-UM cards can be installed in the AMS 6500 ATG system to monitor multiple machines.

Q6: Does the A6500-UM require frequent maintenance?

A6: No, it is designed for continuous operation without maintenance.

Q7: Can the A6500-UM be used for remote monitoring?

A7: Yes, it supports Ethernet-based remote monitoring.

Q8: How does the A6500-UM handle alarm conditions?

A8: It provides digital alarm outputs and supports configurable alarm thresholds.

Q9: Is the A6500-UM compliant with ISO standards?

A9: Yes, it complies with ISO 10816 for vibration monitoring.

Q10: What software is required for configuring the A6500-UM?

A10: It requires AMS Machine Studio software for setup and configuration.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.