Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Description

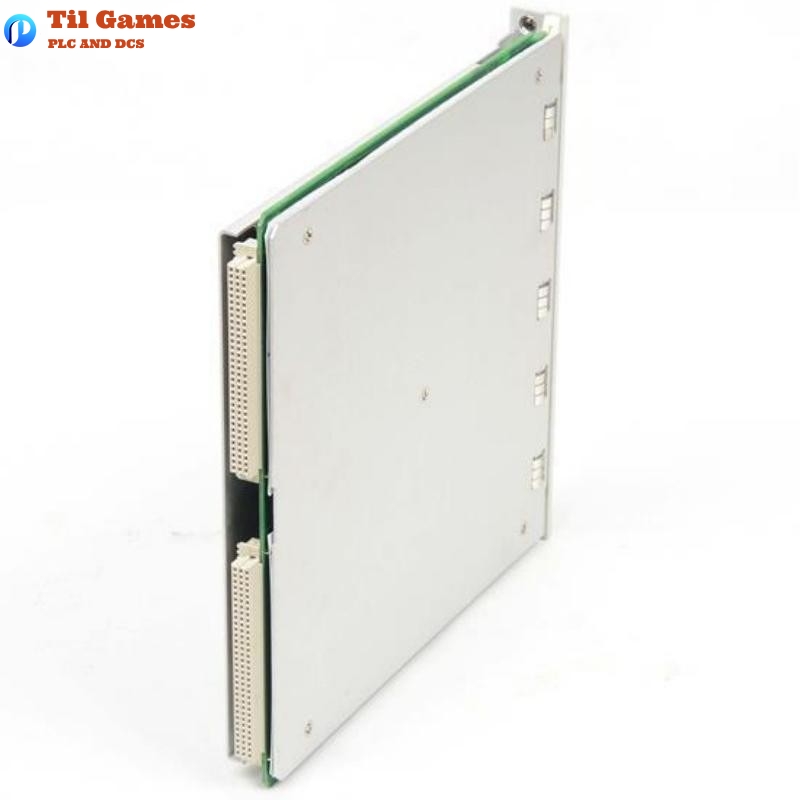

The Bently Nevada 3500/45-01-00 140734-04 Position Monitor is a 4-channel monitoring module engineered to measure the axial and radial position of rotating machinery components. It interfaces with a wide range of transducers, including Proximity Transducers, Rotary Position Transducers (RPTs), DC and AC LVDTs, and Rotary Potentiometers.

The module performs complex signal conditioning and comparison operations, delivering precise position monitoring and triggering configurable alarms when predefined thresholds are breached. It provides key insights into machine behavior, supporting both protection and predictive maintenance.

Each channel pair can be configured independently using 3500 Rack Configuration Software to monitor:

-

Axial (Thrust) Position

-

Differential Expansion

-

Ramp Differential Expansion (Standard/Non-standard/Dual)

-

Complementary Differential Expansion (CIDE)

-

Case Expansion

-

Valve Position

Technical Specifications

| Parameter | Description |

|---|---|

| Channels | 4 channels (programmed in pairs) |

| Input Signal Types | Proximitor, RPT, DC LVDT, AC LVDT, Rotary Potentiometer |

| Power Consumption | 7.7 W (Position I/O), 8.5 W (AC LVDT), 5.6 W (Potentiometer) |

| Input Impedance | 1 MΩ (DC LVDT), 10 kΩ (Proximitor/RPT), 137 kΩ (AC LVDT), 200 kΩ (Potentiometer) |

| Update Rate | ≤ 100 ms |

| Recorder Output | +4 to +20 mA, 0 to 600 Ω load resistance |

| Voltage Compliance | 0 to +12 Vdc |

| Signal Resolution | 0.3662 µA/bit; ±0.25% error at 25°C |

| Signal Conditioning Accuracy | ±0.33% typical, ±1% max |

| Alarm Setpoint Accuracy | Within 0.13% of desired value |

| Alarm Delay (Alert/Danger) | 1–60 s / 0.1–60 s adjustable |

| Operating Temperature | -30°C to +65°C |

| Storage Temperature | -40°C to +85°C |

| Humidity | 95% non-condensing |

| Compliance | FCC, EMC, RoHS, DNV GL, ABS, ATEX, IECEx, cNRTLus |

| Required Rack Space | 1 full-height front slot (Monitor), 1 rear slot (I/O module) |

Dimensions and Weight

| Component | Dimensions (H x W x D) | Weight |

|---|---|---|

| Monitor Module | 241.3 x 24.4 x 241.8 mm | 0.91 kg |

| I/O Module | 241.3 x 24.4 x 99.1 mm | 0.20 kg |

Product Features

-

Accepts a wide range of displacement and position transducer types.

-

Measures and alarms on key mechanical parameters including thrust, expansion, and valve position.

-

Configurable for dual or complementary input expansion measurements.

-

Seamless integration with Bently Nevada 3500 series rack systems.

-

Real-time measurement updates and alarm triggering with configurable delays.

-

Status indication via front-panel LEDs (OK, TX/RX, BYPASS).

-

Robust construction suited for harsh industrial environments.

Product Advantages

-

Flexibility: Supports multiple transducer types and measurement modes.

-

Precision: High accuracy and resolution for reliable monitoring.

-

Protection: Acts as a critical safeguard for rotating machinery by preventing damage.

-

Scalability: Integrates easily with other 3500 modules in large-scale systems.

-

Ease of Configuration: Powerful configuration software enables customization per application.

-

Compliance: Certified for use in hazardous zones and maritime applications.

Applications

-

Axial thrust bearing monitoring in turbines, compressors, and motors

-

Shaft expansion monitoring in steam turbines

-

Valve stem position feedback in process industries

-

Rotor-stator gap monitoring

-

Machine casing thermal expansion tracking

-

Industrial condition monitoring systems requiring accurate position data

Latest Report Title

“Enhanced Shaft Position Reliability Using Multi-Ramp Differential Expansion – 3500/45 Field Study in Petrochemical Turbines (2024)”

Related Models (Same Series or Compatible)

| Model | Function | Key Parameter |

|---|---|---|

| 3500/42M-01-00 | Proximitor Seismic Monitor | 4-channel vibration input |

| 3500/44M-02-01 | Aeroderivitive Vibration Monitor | Measures vibration in gas turbines |

| 3500/46M-01-00 | Hydro Monitor | Monitors shaft position & vibration |

| 3500/25-01-01-00 | Keyphasor Module | 2-channel phase reference for vibration |

| 3500/40M-01-00 | Internal Temperature Monitor | 6-channel RTD input |

| 3500/50-01-01-00 | Tachometer Module | Speed and zero-speed measurements |

Popular Bently Nevada Models

| Model | Description | Primary Use |

|---|---|---|

| 3500/22M-01-01-00 | Transient Data Interface | Dynamic data capture |

| 3500/32M-01-00 | 4-Channel Relay Module | Alarm relay outputs |

| 3500/15-05-01-00 | Power Supply Module | Rack power for 3500 series |

| 3500/93-01-00-00 | Display Interface Module | Graphic display interface |

| 3500/20-01-00-00 | Rack Interface Module | System integration |

| 3500/05-01-01-00 | System Rack | Mounting hardware for modules |

FAQ

Frequently Asked Questions (FAQ)

Q1: What is the primary role of the 3500/45 Position Monitor?

A1: Its role is to provide continuous monitoring of shaft and case position variables to protect rotating machinery by comparing against alarm thresholds.

Q2: How many channels does the monitor support?

A2: The monitor supports four channels, which can be configured in two pairs for simultaneous measurements.

Q3: Which transducers are compatible with the 3500/45?

A3: It is compatible with Proximity Probes, Rotary Potentiometers, DC and AC LVDTs, and RPTs.

Q4: Can the 3500/45 perform differential expansion monitoring?

A4: Yes, it can monitor standard, non-standard, dual, and complementary differential expansion.

Q5: Is it suitable for hazardous environments?

A5: Yes, it is certified for Class I, Division 2 and Zone 2 hazardous areas with ATEX, IECEx, and cNRTLus approvals.

Q6: How accurate are the position measurements?

A6: The typical accuracy is within ±0.33% of full-scale, with a maximum of ±1%.

Q7: What is the update rate for the measurements?

A7: The update rate for all monitored parameters is 100 milliseconds or less.

Q8: Can the module output analog signals for external recorders?

A8: Yes, it supports 4–20 mA analog outputs for each channel, scalable to full-scale measurements.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.