Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Product Description

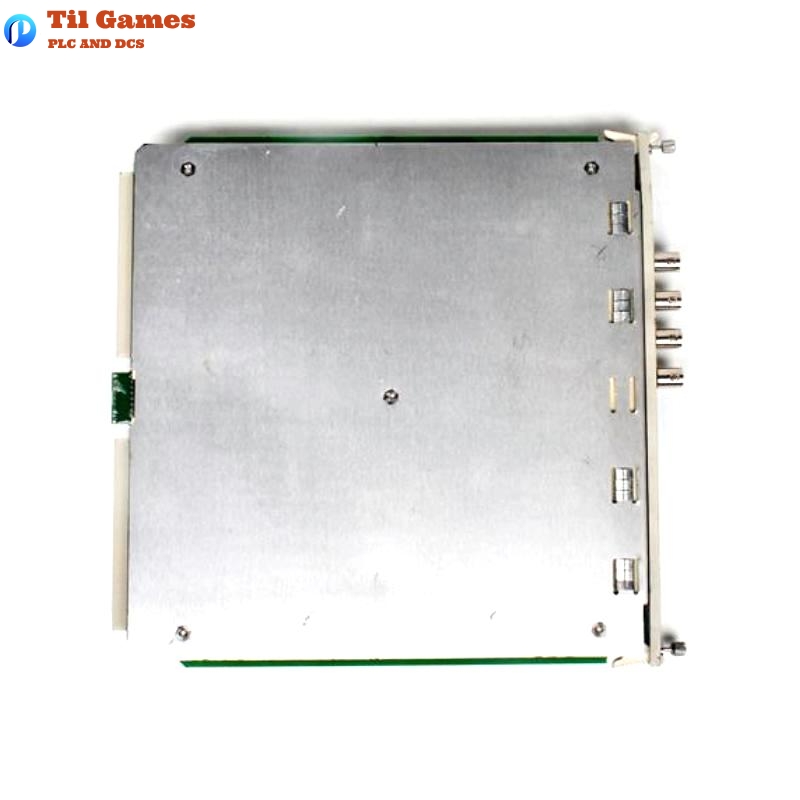

The Bently Nevada 3500/44M Aeroderivitive GT Vibration Monitor is a four-channel monitoring module specifically designed for aeroderivative gas turbines. It provides continuous condition monitoring of critical rotating machinery by measuring, integrating, and evaluating vibration and Keyphasor® data.

It enables real-time analysis by comparing measured vibration parameters against configurable alert and danger setpoints. The module supports multiple operating modes and offers advanced signal filtering capabilities, including 1X tracking, bandpass filtering, and signal integration. Each channel pair can independently track different Keyphasor® signals, enhancing monitoring flexibility for dual-shaft machines.

This monitor seamlessly interfaces with Bently Nevada Velomitor® sensors and accelerometers via Prox/Velom and Multimode I/O modules, ensuring comprehensive vibration diagnostics for both operations and maintenance personnel.

Technical Specifications

General Parameters

| Parameter | Description |

|---|---|

| Product Name | Bently Nevada 3500/44M Aeroderivitive GT Vibration Monitor |

| Channel Count | 4 |

| Input Types | Velomitor sensors, Accelerometers, Interface Modules (86517, 86497) |

| Power Consumption | 7.7 W (typical) |

| Rack Slot Requirements | 1 full-height front slot (Monitor), 1 full-height rear slot (I/O module) |

| Output Signal (Recorder) | +4 to +20 mA, proportional to full-scale |

| Update Rate | ≤ 100 ms |

| Alarm Time Delay | Alert: 1–60 s, Danger: 0.1–60 s |

| Alarm Accuracy | ±0.13% |

| Voltage Compliance (Output) | 0 to +12 Vdc across 0–600 Ω load |

Dimensions and Weight

| Component | Dimensions (H x W x D) | Weight |

|---|---|---|

| Monitor Module | 241.3 x 24.4 x 241.8 mm | 0.91 kg |

| I/O Module | 241.3 x 24.4 x 99.1 mm | 0.45 kg |

Signal Conditioning

| Filter Type | Frequency Range / Roll-off |

|---|---|

| Direct Signal | 4 Hz – 30 kHz |

| Bandpass (Low-Pass) | Corner: 200 Hz, Rolloff: 200 dB/decade (10-pole) |

| Bandpass (High-Pass) | Corners: 25, 75, or 100 Hz, Rolloff: 200 dB/decade (10-pole) |

| Tracking Filter | 2400–18,000 RPM, Bandwidth: 3 or 5 Hz, Rolloff: 120 dB/decade (6-pole) |

Key Features

-

Four Independent Channels

Simultaneous multi-channel monitoring for velocity and acceleration inputs. -

Advanced Filtering Options

Includes signal integration, band-pass, and 1X tracking filters for targeted diagnostics. -

Multimode Monitoring

Supports up to eight sets of alarm parameters, switchable based on machine mode. -

Dual Keyphasor Support

Two independent Keyphasor signal inputs enable dual-shaft machine monitoring. -

Buffered Outputs & Recorder Integration

Front coaxial connectors for each channel with short-circuit protection and recorder outputs. -

Rugged Compliance Certifications

Complies with EMC, FCC, ATEX, and marine certifications for use in industrial environments.

Product Advantages

-

Optimized specifically for aeroderivative gas turbines

-

Precise vibration measurement for enhanced machine reliability

-

Seamless integration with Bently Nevada Velomitor® and Proximitor® technologies

-

Flexible system configuration with user-friendly 3500 Rack Configuration Software

-

Suitable for harsh industrial environments with wide certification coverage

Applications

-

Aeroderivative gas turbine condition monitoring

-

Oil and gas industry turbine diagnostics

-

Power generation plant turbine protection

-

Industrial and marine propulsion systems

-

Aerospace turbine equipment monitoring

-

Combined cycle and cogeneration facilities

Latest Technical Reports and Documents

-

Title: 3500/44M Aeroderivitive GT Vibration Monitor Datasheet – 143441 Rev. U

Publisher: Baker Hughes

Year: 2024

Available at: bntechsupport.com

Recommended Related Models (Same Series or Complementary)

| Model | Description | Input Type | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/42M | Proximitor Seismic Monitor | Proximity/Seismic | 241.3 x 24.4 x 241.8 | 0.91 |

| 3500/40M | Proximitor Monitor | Proximity Transducers | 241.3 x 24.4 x 241.8 | 0.91 |

| 3500/50 | Tachometer Module | Keyphasor Transducers | 241.3 x 24.4 x 241.8 | 0.91 |

| 3500/60 | Temperature Monitor | Thermocouples / RTDs | 241.3 x 24.4 x 241.8 | 0.91 |

| 3500/25 | Keyphasor Module | Keyphasor Probes | 241.3 x 24.4 x 241.8 | 0.91 |

| 3500/32M | 4-Channel Relay Module | Relay Outputs | 241.3 x 24.4 x 241.8 | 0.91 |

Popular Bently Nevada Models

| Model | Description | Application | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|

| 3500/22M | Transient Data Interface | Data Interface Module | 241.3 x 24.4 x 241.8 | 0.91 |

| 3500/15 | Power Supply Module | 3500 System Power | 241.3 x 24.4 x 241.8 | 0.91 |

| 3500/94M | Display Interface Module | 3500 System Display | 241.3 x 24.4 x 241.8 | 0.91 |

| 3701/40 | TMR Vibration Monitor | Triple Modular Redundancy | 241.3 x 24.4 x 241.8 | 0.91 |

| ADAPT 3701/55 | Adaptive Machine Monitoring | Condition-Based Monitoring | 241.3 x 24.4 x 241.8 | 0.91 |

| 3300 XL 8 mm Proximitor | Proximity Transducer System | Rotating Equipment Monitoring | 80 x 16 mm (Probe) | 0.15 |

FAQ

Frequently Asked Questions (FAQ)

Q1: What is the primary function of the 3500/44M Aeroderivitive GT Vibration Monitor?

A1: It continuously monitors vibration levels in aeroderivative gas turbines and triggers alarms based on preset limits.

Q2: How many channels does the module support?

A2: The 3500/44M supports four fully independent monitoring channels.

Q3: Can the monitor track dual-shaft turbines?

A3: Yes, it accepts two Keyphasor signals, enabling it to track two separate shafts.

Q4: What sensors are compatible with this monitor?

A4: It supports Velomitor sensors, accelerometers, and Bently Nevada interface modules (86517, 86497).

Q5: How is signal conditioning achieved?

A5: Signal filtering includes bandpass, 1X tracking, and signal integration to extract meaningful diagnostics.

Q6: What are the output options?

A6: Outputs include +4 to +20 mA recorder outputs, buffered transducer signals, and LED status indicators.

Q7: Is the 3500/44M certified for hazardous environments?

A7: Yes, it complies with cNRTLus, ATEX/IECEx, and DNV GL certifications for Class I, Div 2 and Zone 2.

Q8: How does the alarm configuration work?

A8: Each channel supports up to eight alarm sets with customizable alert and danger levels and programmable delays.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.