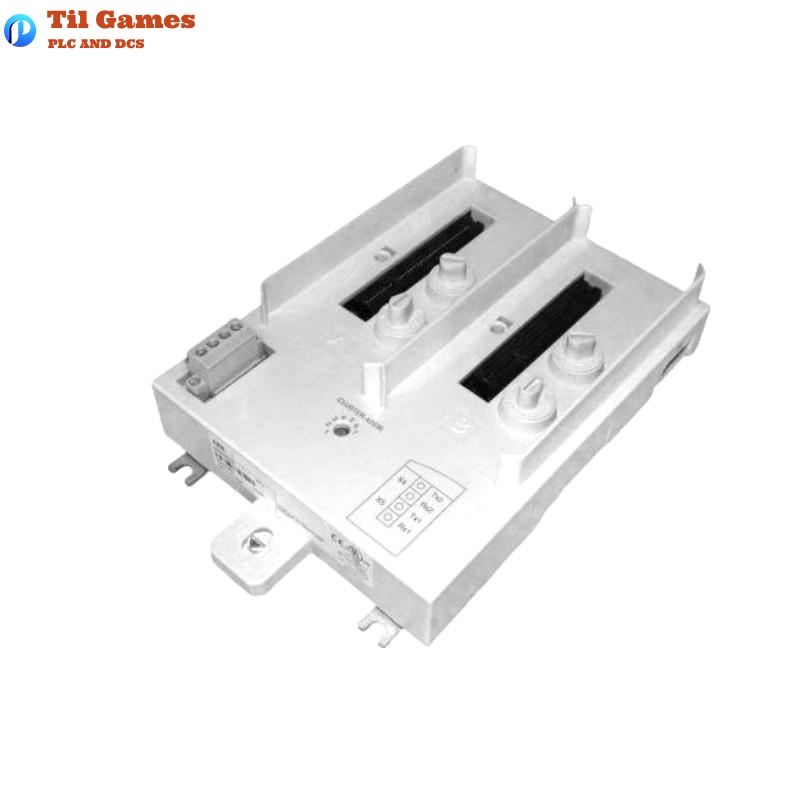

Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Technical Specifications

| Parameter | Specification |

|---|---|

| Article Number | 3BSE020848R11 |

| Communication Protocol | Modulebus |

| Line Redundancy | Yes |

| Hot Swap | No |

| Power Input | 24 V d.c (19.2 – 30 V) |

| Mounting | Vertical or Horizontal |

| ModuleBus Current Distribution | Maximum 5 V: 1.5 A, 24 V: 1.5 A |

| Mechanical Keys | 36 different combinations |

| Acceptable Wire Sizes | Solid: 0.2 – 2.5 mm²; Stranded: 0.2 – 2.5 mm², 24 -12 AWG |

| Rated Insulation Voltage | 50 V |

| Dielectric Test Voltage | 500 V a.c |

| Power Dissipation | 2.0 W |

| Ingress Protection | IP20 (IEC 60529) |

| Temperature, Operating | 0 to +55 °C (+32 to +131 °F) |

| Temperature, Storage | -40 to +70 °C (-40 to +158° F) |

| Relative Humidity | 5 to 95 %, non-condensing |

| Dimensions (W x H x D) | 124 mm x 186 mm x 47 mm |

| Weight | 0.45 kg |

FAQ

FAQ

Q1: What is the primary function of the ABB TU841 Termination Unit?

A1: The TU841 is used to connect TB840/TB840A to non-redundant I/O systems. It is a passive unit for power supply and ModuleBus connections.

Q2: Can I mount the TU841 vertically and horizontally?

A2: Yes, the TU841 can be mounted both vertically and horizontally based on your system’s requirements.

Q3: What is the purpose of the mechanical keys in the TU841 module?

A3: The mechanical keys are used to prevent the insertion of incorrect module types. There are 36 different keying combinations.

Q4: What wire sizes are acceptable for the TU841 module?

A4: The module accepts solid wires from 0.2 to 2.5 mm² and stranded wires from 0.2 to 2.5 mm², including 24 to 12 AWG.

Q5: Does the TU841 support hot swapping?

A5: No, the TU841 does not support hot swapping.

Q6: What is the rated insulation voltage for the TU841?

A6: The rated insulation voltage is 50 V.

Q7: What certifications does the TU841 have for hazardous locations?

A7: The TU841 is certified for Class 1 Zone 2 hazardous locations and ATEX Zone 2.

Q8: What is the recommended torque for the wiring terminals?

A8: The recommended torque for the wiring terminals is 0.5 Nm.

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.