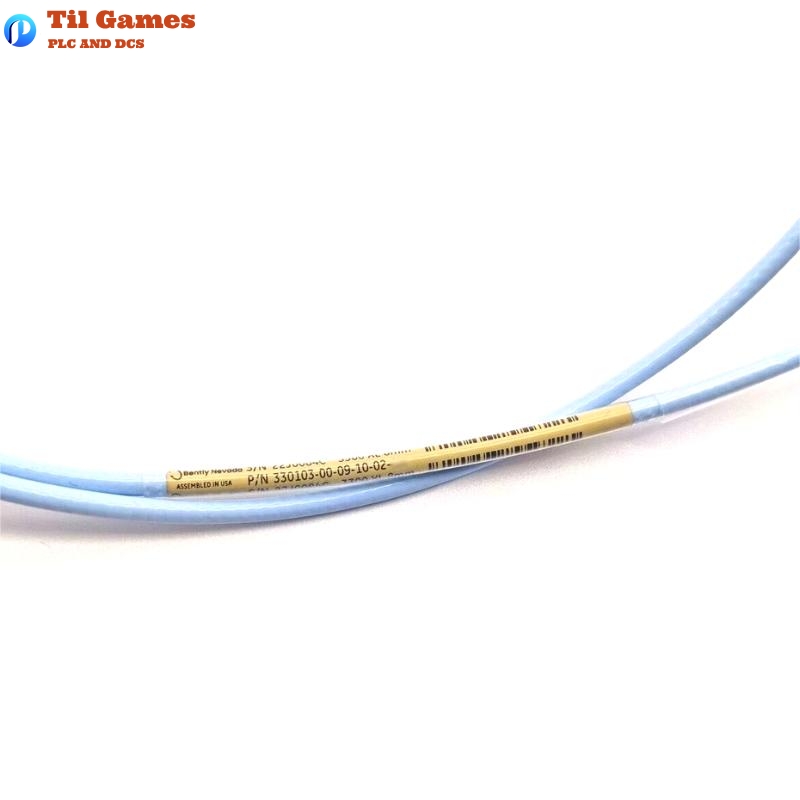

Products Description

| Company Information | |||

| [email protected] | |||

| Mobile | +8613666033393 | ||

| +8613666033393 | |||

| 13666033393 | |||

| Add | Room 1004, No. 62 Xiangxiu Li, Siming District, Xiamen City, Fujian Province, China |

Technical Specifications

| Parameter | Description |

|---|---|

| Product Type | Proximity Probe |

| System | 3300 XL 8 mm Proximity Transducer System |

| Probe Tip Diameter | 8.0 mm |

| Thread Size | M10 x 1 |

| Connector Type | Miniature coaxial ClickLoc |

| Total Length | 1.0 meter |

| Weight | 0.323 kg (323 g) |

| Cable Type | 75 Ω triaxial, FEP insulated |

| Material – Probe Tip | Polyphenylene sulfide (PPS) |

| Material – Probe Case | AISI 303 or 304 stainless steel |

| Operating Temperature (Probe) | -52°C to +177°C (standard); up to +218°C (ETR) |

| Operating Temperature (Extension Cable) | -52°C to +177°C (standard); up to +260°C (ETR) |

| Operating Temperature (Proximitor Sensor) | -52°C to +100°C |

| Storage Temperature (Proximitor Sensor) | -52°C to +105°C |

| Recommended Gap Setting | 1.27 mm (50 mils), corresponding to -9 Vdc |

| Linear Range | 2 mm (from 0.25 mm to 2.3 mm) |

| Incremental Scale Factor (ISF) | 7.87 V/mm ±5% for 1 m system |

| Frequency Response | 0 to 10 kHz, +0, -3 dB |

| Min. Target Size | 15.2 mm (0.6 in) |

| Min. Shaft Diameter | 50.8 mm (recommended 76.2 mm) |

| Tensile Strength (Probe Tip to Cable) | 330 N (75 lbf) |

| Environmental Ratings | IP54 minimum, CE compliant, ATEX/IECEx certified |

| Certifications | FCC, EMC Directive 2014/30/EU, RoHS Directive 2011/65/EU |

| Hazardous Area Approvals | Class I, Div 1 & 2, Zone 0/2 with appropriate barriers |

FAQ

Frequently Asked Questions (FAQ)

Q1: What is the purpose of the Bently Nevada 330103-00-09-10-02-00 proximity probe?

A1: It measures shaft vibration and position in rotating machinery using non-contact eddy current technology.

Q2: What is the linear measurement range of this probe?

A2: It provides a linear range of 2 mm (from 0.25 mm to 2.3 mm gap).

Q3: Is this probe compliant with API 670 standards?

A3: Yes, the 3300 XL 8 mm system is fully compliant with API 670 mechanical configuration and performance standards.

Q4: Can the probe operate in high-temperature environments?

A4: Yes. The standard version operates up to 177°C. The ETR version supports up to 218°C for the probe and 260°C for the cable.

Q5: What is the recommended installation torque for the probe?

A5: For standard M10x1 forward-mount probes, the recommended torque is 7.5 N·m (66 in·lbf).

Q6: Is this probe compatible with older Bently Nevada systems?

A6: Yes. The 3300 XL 8 mm components are backward compatible with non-XL 3300 5 mm and 8 mm series systems.

Q7: What is the total system weight of a 1.0-meter configuration?

A7: The typical total system weight is approximately 0.323 kg for the 1.0-meter probe only (excluding sensor and cable).

Q8: What is the probe’s cable bend radius?

A8: The minimum permissible cable bend radius is 25.4 mm (1.0 inch).

Tags

Packing & Delivery

We will use wear-resistant cartons to seal the boxes, and take photos for your confirmation before sealing. We will pack the boxes only after confirmation.

For express delivery, we will use DHL, UPS, TNT, FedEx and EMS.

Please rest assured that we have a deep cooperation with express delivery companies and can ensure that your goods are delivered to you in good condition.